Bitumen

Bitumen loading and moving

What is bitumen? and its various uses

Bitumen is a black, paste-like substance that is used in moisture insulation and asphalt construction. There are different types of bitumen, each of which has a specific application. Bitumen is a derivative of oil and is often produced in an oil refinery.

Bitumen is a black to dark brown hydrocarbon material that dissolves completely in carbon sulfide and carbon tetrachloride. Bitumen is solid at ambient temperature. But as the temperature increases, it turns into a paste and then becomes liquid.

The important use of bitumen is due to the presence of two important properties of this substance;

* Impermeable to water

* Stickiness

Bitumen is usually obtained from the distillation of crude oil. Such bitumen is called petroleum bitumen or distillate bitumen. Oil bitumen is the product of two stages of crude oil distillation in the distillation tower. In the first stage of distillation, light substances such as gasoline and propane are separated from crude oil. This process is carried out in a pressure close to one atmosphere (unit). In the second stage, heavy compounds such as diesel and kerosene are removed. This process takes place in a pressure close to vacuum. Finally, a mixture of very fine solid particles called asphaltene remains, which is immersed in a grease-like fluid called maltene.

But some types of bitumen are obtained in nature as a result of the gradual transformation of crude oil and the evaporation of its volatile substances over many years. Such bitumen is called natural bitumen and it is more durable than petroleum bitumen. Such bitumen may exist in pure form in nature (lake bitumen) such as Behbahan Bitumen Lake in Iran and Trinidad Bitumen Lake in America, or it may be extracted from mines.

Types and sources of bitumen and applications

Bitumen is a hydrocarbon substance that has a definition, characteristics, sources and special characteristics. Bitumen materials are more diverse than oil, because bitumen has other sources besides oil. Bitumens are divided into the following three categories depending on their origin:

A- Natural bitumen

2- Petroleum bitumen

3- Tar tars

Natural bitumen

Natural bitumen is a natural hydrocarbon resin that has been found in the Bonita River in northeastern Utah in recent history. This natural asphalt is similar to a hardened crude oil asphalt. Usually, the names of asphalt, yutanite and asphaltum are also used for this material. Natural bitumen, like natural asphalt, is soluble in aliphatic and aromatic solvents. Due to the high compatibility of this product, it is usually used to harden diluted petroleum derivatives.Natural bitumen is a shiny, black and very brittle substance in lump form, very similar to obscenity, and in micronized powder form, it has a dark brown color. Natural bitumen is found underground in vertical layers. Because of the narrow mining front, natural bitumen is extracted today using excavators, loaders, hammers and other new mechanical tools.

Petroleum bitumen

Petroleum bitumens are solid and semi-solid bitumens that are obtained directly from the distillation of crude oil or by other additional operations such as air blowing. Oil bitumen is the residue or heavy residue of crude oil distillation. The amount of bitumen in crude oil varies from zero to more than half of it. In addition, bitumens obtained from different sources can have many differences. Therefore, bitumen producing refineries must choose their crude oil carefully to ensure the quality of bitumen.

Direct extraction of bitumen from crude oil

Distillation is an essential process in refining crude oil. The first stage of distillation is done under atmospheric pressure and usually involves heating the crude oil to a temperature of about 650 to 800 degrees Fahrenheit and then injecting it into a separation column. In this way, the lighter cuts as a product of the top of the tower and the bituminous residue are called atmospheric residue. This is the first step in the entire purification process. Many crude oils contain high percentages of high-boiling fractions that cannot be distilled in an atmospheric still. To separate these cuts and prepare bitumen with desired characteristics, a secondary separation tower that works in vacuum conditions is used.

The remainder of this process is called direct extraction bitumen. Asphalt production process by vacuum distillation method has very little effect on other bitumen properties except permeability. The origin of the used crude oil also has a significant effect on the physical properties of extracted bitumen.

Tar pitch

Different types of bitumen chemically, there are different classifications for bitumen, the two most common of which are the classification based on whether the bitumen is natural or petroleum, and the more common one is based on the type of bitumen source, i.e. oil, coal, or wood.

(Tar) Bitumen This type of bitumen is sometimes known by the same name due to its similarity in appearance and similar use to petroleum bitumen. Because the source of this type of bitumen is different from petroleum bitumen, it has different chemical composition and physical properties, which is a general word for liquids that have a different behavior during use and performance in service than burning natural organic materials such as wood or coal. Stone and their destructive distillation is in the absence of air. Two types of tar can be prepared from coal burning or carbonization according to the type of process:

1. A process that results in bitumen with a high percentage of aromatics is a bitumen that is obtained at a temperature of 600 degrees Celsius and has a low percentage of triaromatics, which is the remaining material of coal tar after cooling the vapors and separating the oily fractions.

BS is obtained with oil cuttings and Pich standard is produced by mixing (refined tar) refinery bitumen, which has 8 different grades after tar and pitch. In the age of industrial revolution in Europe, a large amount of oil and gas resources appeared, coal was almost abandoned and its consumption was greatly reduced.

Today, 90% of these products are used in the four application groups of road construction, mold coal soil, charcoal electrodes, and glazing and coating of pipes, but the use of bitumen obtained from refinery coal on roads is only limited to the mixture for surface coatings and this The reason is that these bitumens are more soluble and have better performance at low temperatures, and as a result, they create better adhesion, but the main weakness of these bitumens is their greater thermal sensitivity compared to petroleum bitumen.

Four applications of tar:

1- Road construction (Road Tar)

2- Briquettin

3- Charcoal electrodes (Electrode Binder)

4- Pipe Enamels

The use of bitumen obtained from tar on the road is limited to bitumen-tar mixture for surface coatings. The coal bitumen used in this mixture is more soluble at low temperature and has better performance. In general, it is believed that because the acidity of tar is high, it creates good adhesion with materials.

Therefore, wetting of materials is better and adhesion is improved, but due to environmental problems and the development of chemical adhesion agents, the use of tar is limited. Although the use of tar can be used because it is less affected by oil and diesel leaks in vehicle parking areas and similar cases, the main drawback of tar can be its greater thermal sensitivity than bitumen. He knew oil.

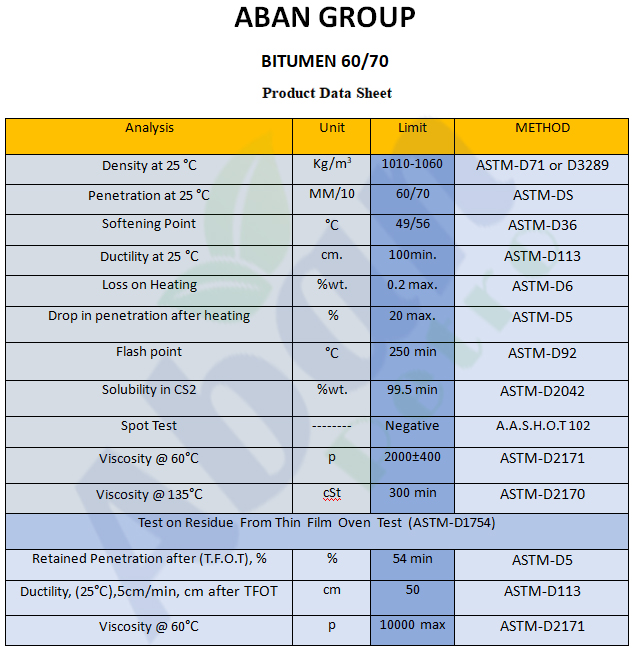

Bitumen specifications

1- Degree of influence:

Penetration degree test is used to determine bitumen hardness. In this test, it penetrates into bitumen at a temperature of 25 degrees from a standard needle under the effect of a load of 100 grams in 5 seconds. The amount of penetration in tenths of millimeters is called the degree of penetration. The lower the degree of penetration, the harder the bitumen.

2-viscosity:

The higher the flow rate of bitumen, the more solid properties it exhibits. It is clear that the mental retardation is less at higher temperatures. This characteristic of bitumen is measured with C-bolt Fiorel device or by kinematic method.

3- Degree of ignition:

The degree of ignition is the temperature at which if the bitumen reaches that temperature, the gases emitted from it will ignite as the flame approaches and a flame will appear on its surface. The maximum temperature that bitumen can be heated in the workshop is limited to the degree of ignition.

4- Weight loss:

The weight loss of bitumen at high temperature is due to the evaporation of part of its oils and petroleum compounds. This feature is also one of the important properties of bitumen. The weight loss of bitumen is measured in the oven at 163°C and for 5 hours (approximate asphalt curing conditions).

5- Plasticity or stigma:

If we pull a sample of bitumen with a cross-sectional area of 1 cm2 at a speed of 5 cm/min, the length increase of the sample before breaking is called the enemic property of bitumen.

6- Degree of purity:

We know that the solvent of bitumen is carbon tetrachloride and carbon sulfur. Therefore, if we dissolve a sample of bitumen in any of these materials, its impurities will remain and from there we can determine the degree of purity of the bitumen. The degree of purity is: (bitumen sample weight) ÷ [(impurity weight) – (bitumen weight)]

7- Degree of softness:

Softness degree is the temperature at which bitumen turns from solid to liquid when bitumen reaches that temperature. The higher the degree of bitumen softness, the less sensitive it is to temperature changes. The degree of softness of ordinary bitumen is about 60 to 70.

(180 and 220 kg barrels, tankers, bulk carriers and playbacks)

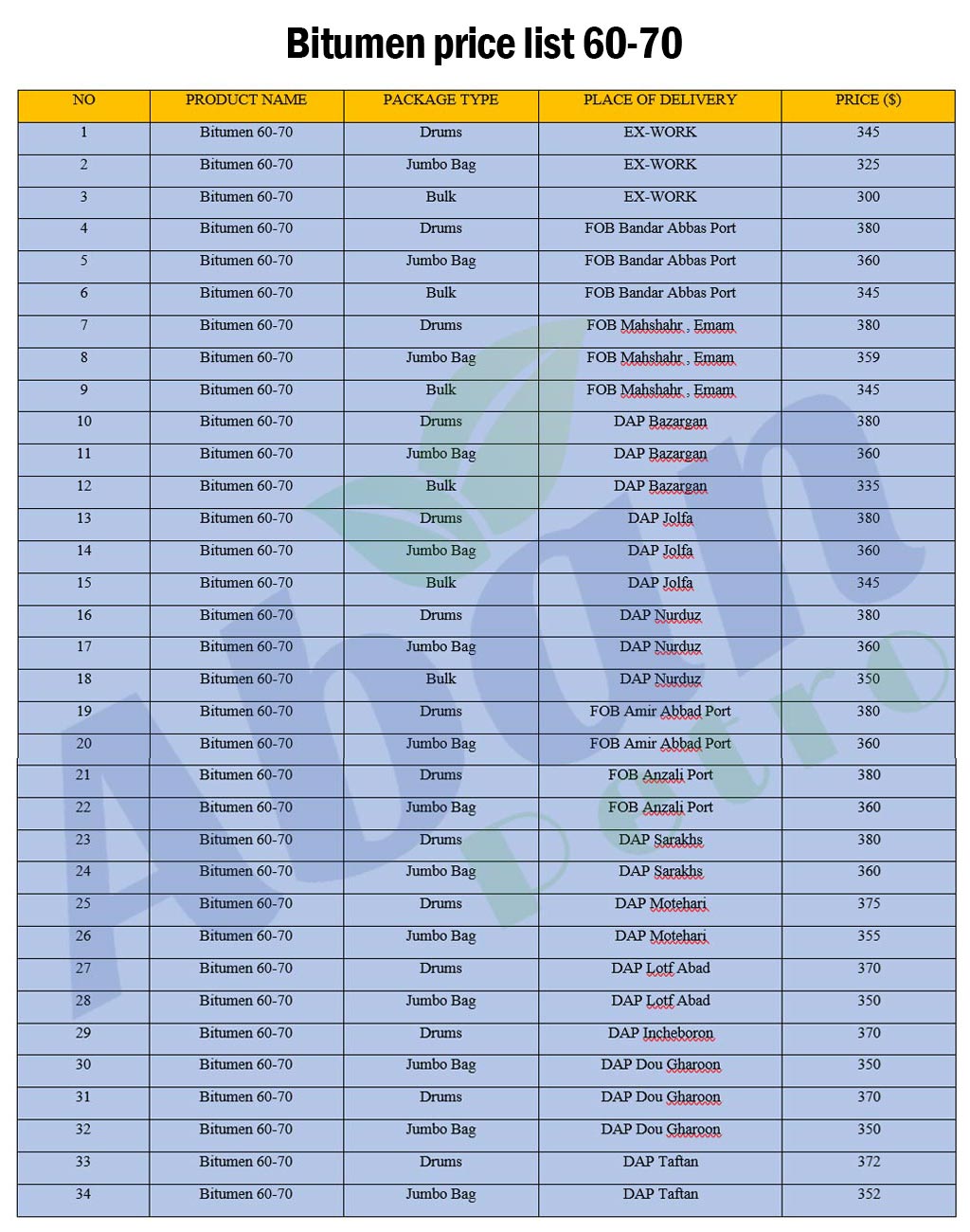

Bitumen price list 60-70